1.0

INTRODUCTION

Thermal properties are of interest in

many different applications as a computer chip cannot operate and perform its required

function if it overheats. Dissipation of heat while the chip is operating is

dependent on convection through the surrounding air, radiation, and conduction

through other components adjacent to the chip. Higher thermal conductivity of these

parts is vital to quickly dissipate the heat from the chip. By determining this

thermal property for different materials, selection of the appropriate material

for specific conditions is possible. In

this report the experimental methods for determination of thermal conductivity

will be discussed.

2.0 EXPERIMENTAL METHODS

2.1 Thermal Conductivity Apparatus Method

The TD-8561 Thermal Conductivity

Apparatus may be used determine the thermal conductivity. The procedure for measuring

thermal conductivity using the stated apparatus is straightforward. A slab of the material to be tested is clamped

between a steam chamber, which maintains a constant temperature of 100 °C, and

a block of ice, which maintains a constant temperature of 0°C. A fixed temperature

differential of 100 °C is thereby established between the surfaces of the

material. The heat transferred is measured by collecting the water from the

melting ice. The ice melts at a rate of 1 gram per 80 calories of heat flow (the

latent heat of melting for ice).

The

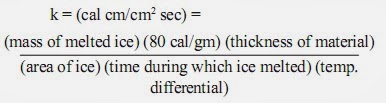

thermal conductivity, k, is therefore measured using the following equation:

where

distances are measured in centimeters, masses in grams, and time in seconds.

The

Thermal Conductivity Apparatus includes the following equipment as:

- ü Steam chamber with hardware for mounting sample

- ü Ice mold with cover

- ü Materials to test: Glass, wood, lexan, masonite, and sheet rock (The wood, masonite, and sheet rock are covered with aluminum foil for waterproofing.)

Equipment Included with the

Thermal Conductivity Apparatus

2.2 Pulsed or Periodic Regime

This

method uses the heat conduction through metals through the Single thermal

pulse, applied to both ends, and subsequent evolution through the three

monitored points;

The

material to be tested for thermal conductivity in the form of bar are wrapped

in a heating resistor to some length.

Montagem:

Mineral wool sandwich covering the metal cylinders.

Three

batches of thermometers are placed on different location on the bar. The heat

sink keeps one of the ends at room temperature and is the reference point for

the position axis. The bar is mounted in the middle of two layers of thermal

insulation material (mineral wool) that prevent heat convection and minimize

thermal losses.

In a pulsed or periodic regime, an

electric current is applied to the heating resistor that heats that end through

Joule's effect. The heat generated will run through the bar and be dissipated

at the opposite end in sink.

In

the periodic mode, the temperature reading has two components:

ü One comes from the oscillation of

the heating itself, its period being the same as the heat source (on and off);

ü The other is the average heating of

the bar as a whole, which is almost exponential.

Through

a graphical fitting of a function to the average temperature, the oscillating

values can be extracted by subtracting the average. By analyzing the

oscillating data, the heat propagation constant may be determined by Fourier

analysis or a simple sinusoidal fitting.

2.3 ANGSTROM’S METHOD

Angstrom developed a method of determining

the thermal conductivity of a metal rod by applying an alternating heat pulse

to one end while leaving the other end at room temperature. Doing this causes a

heat wave to propagate down the rod and creates an observable temperature

difference between two points on the rod. This also creates a varying phase

relationship between the measured temperature recorded at the first and second

points.

The thermal conductivity of the rod

can be determined if the temperature of these two points is measured as a

function of time. Since the temperature changes are periodic, the measurements

of the power input used to heat the system are not required. Because of this,

absolute measurements of the temperature are not required so that only relative

changes in magnitude of temperature as a function of time and position must be

recorded. The thermistors may be used to respond linearly over changes of a few

degrees.

No comments:

Post a Comment