The main cause of turbine blade failure is high cycle fatigue. Fatigue

failure is related to repeat cycling of the load on a structural member. The

fatigue life of a structural member i.e. the number of load cycles it can

survive is in general determined by the magnitude of the stress cycles. The

exact relation between the magnitude of the stress and the fatigue life depends

on the material properties of the structural member. In general higher stresses

lead to a shorter fatigue life. For some materials fatigue only occurs if

stresses exceed a certain minimum level for other materials there is no minimal

stress level. If the stresses that are present on the turbine blade during

operation and the material properties of the turbine blade are known then an

estimation of the fatigue life of the turbine blade can be made.

Generally fatigue failure occurs as follows. After a number of load

cycles a crack is initiated. This usually occurs at a point of relatively high

stress concentration i.e. points with sharp geometrical discontinuities or

points with relatively rough or soft surfaces. Once the crack is initiated it

advances incrementally through the material with each stress cycle. In general

this advance is very slow up to a certain point where it accelerates. The final

failure occurs very rapidly. High cycle fatigue corresponds to failure after a

relatively large number of load cycles. High cycle fatigue occurs at stress

levels well below the yield strength of the material where deformation is

elastic. The failure of a structural member is not caused by excessive loading

but by the repeated cycling of the load.

Another cause of static stress failure of blades is blade overheating

related to the departures from normal operating conditions. Such failures are

detected by metallographic methods based on metal structural variations throughout

the entire blade section or in its separate regions as well as on the formation

of thick de-alloyed surface layers. Thus, cracks on ZhS6K-alloy guide blade

edges were discovered after GT adjustment testing for 103 h. with 57 start-ups.

Coating cracking is induced by a local corrosion failure of blade base

metal under the coating. A method for testing small-size coating specimens has

been developed. The method makes it possible to observe strain relief

characteristics during testing and to study the mechanisms of crack initiation

and propagation in a coating up to specimen failure. A series of thermal

fatigue tests was performed using different super alloy specimens with

different coatings. The mechanisms of micro-crack initiation and suppression in

multi-layer coatings have been determined.

LIFE PREDICTION UNDER CREEP & FATIGUE LOAD

The life prediction, more generally

the evaluation of the behaviour of a rupture mechanism, or several mechanisms

at the same time, is a significant task in order to ensure the reliability of

the system. The cycle is non reversible to deal with the mean stress;

equivalent reversible stress is calculated with the

Goodman rule .

Life prediction for fatigue (Nf):

Nf

is defined in this work by the Manson Coffin formulation. Manson Coffin

established that the alternative strain is related to the number of stress

cycles to rupture, by the equation:

E is the elasticity modulus, σf material strength, and b

and c for the majority of materials

are equal to -0.12 and - 0.6.

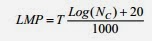

Life prediction for creep (Nc):

Creep for metal is described by the

Larson Miller parameter (LMP). T is the temperature in K degrees; Nc

is the time to creep rupture in hours. The LMP C coefficient is taken equal to

20.

Model for fatigue-creep interaction:

Many approaches have been developed

these last years to predict the safe life of materials subjected to high

temperatures. To consider the interaction between fatigue and creep damage,

several rules of damage accumulation could be used. This accumulation can be

considered as linear or non linear. In this work two damage accumulation models

are used: the linear Miner rule eq. and the non linear Chaboche rule.

It is considered that during a cycle,

the damage of creep passes from the damage D0 to D1 and that the fatigue damage

increases at the end of the cycle from D1 to D2. Two equations and give

respectively the creep and fatigue interactive damage for one cycle:

The coefficients α, β and k are the

material data, defined experimentally. In the two cases, the damage is complete

when damage accumulation reaches the unity. Then the rupture becomes certain.

We can then predict the number of cycles to failure when:

No comments:

Post a Comment