Metal cutting fluid is utilized as a part of metalworking

and machining for various purposes, mostly as a lubricant and for cooling. It

comes in the different type of forms including synthetic fluids, semi-synthetic

fluids, oils and solvent oils.

Synthetic fluids are made of alkaline mixes and compounds

that avert erosion. They are utilized as a part of weakened water and are the

critical part of cooling. Semi-synthetic fluids are a blend of soluble oils and

manufactured fluids and its attributes show up in the two constituents.

Undiluted Oils are used only when making cutting fluids.

They offer the best friction yet bad cooling. Solvent oils are solute with

water and give great lubrication and cooling contrasted with alternate items.

They are the most cost-effective and are hence are very popular among the heavy

metal cutting industry.

In order to select the best oil, you need to gather some

basic information relevant to the selection criteria. For purposes of

simplicity, you need to know the metals in use, the predominant machining

operations, basic machine types, tooling specifics, plant processes and

chemical restrictions for your facility.

Metals

Some metals are more difficult to machine than others.

Stainless steel, exotic alloys and very hard metals demand a very high level of

performance from the cutting oil. Other metals, like brass and aluminum, are

easy to machine with general-purpose oils.

Where tough, low-machinability metals are involved, you will

need highly additized cutting oil with excellent extreme-pressure (EP) and

anti-weld capability. Most often, these oils contain active sulfur and chlorine

to protect the tooling and ensure good parts finish.

For brass, aluminum, many carbon steels and low-alloy

steels, a cutting oil with lubricity additives, friction modifiers and mild

EP/anti-weld performance is sufficient. These oils are generally formulated

with sulfurized fat (inactive) and/or chlorinated paraffin. Active cutting oils

(containing active sulfur) should not be used for brass and aluminum, as they

will stain or tarnish the finished parts. Oils formulated for brass and

aluminum are often called "non-staining" oils.

Machining Operations

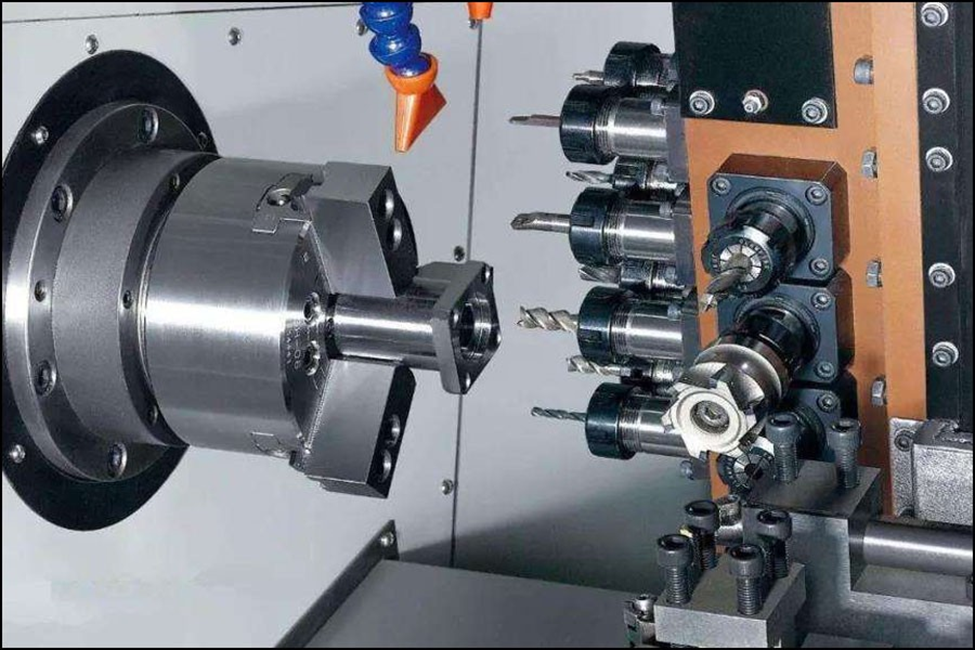

Easy machining operations (turning, forming, drilling,

milling, etc.) can be performed at higher speeds and require high levels of

cooling with only modest EP capability. The milder operations can be performed

with lower viscosity, lightly additized fluids.

Difficult machining operations must be run at lower speeds

and require a great deal of anti-weld protection. Oils designed specifically

for the most difficult operations, like thread-cutting or broaching, are

generally higher in viscosity and loaded with EP additives like active sulfur

and chlorine.

Basic Machine Types

The type of machinery will also dictate some of the cutting

oil characteristics. For example, screw machines experience heavy

cross-contamination between the lube oil and cutting oil. For this reason,

these machines frequently run on dual-purpose or tri-purpose oils that can be

used in the lube boxes, hydraulics and cutting oil sumps.

Grinders, gun drills and deep-hole drilling machines require

lighter viscosity oils for high rates of cooling, good chip and swarf flushing,

through-the-tool delivery and high-pressure application without foaming. CNC

OEMs may place restrictions on the cutting oil due to potential incompatibility

between the cutting fluid and machine components, such as seals. Centerless

grinders may require a tougher fluid than surface grinders.

Qualities and

Functions of a Good Metal Cutting Fluid:

· The principle trademark is its ability to keep

the metal and apparatus temperature stable to abstain from obliterating the

metal because of high temperatures or even a fire on nearby materials.

·

It ought to give appropriate lubrication to

boost the life cycle of the cutting tip and lessen the amount of heat created

by reducing contact.

·

It ought to have the ability to stop rust from

getting on the metal cutters and important metal parts.

·

The cutting fluid must be safe to operate and

also environmental friendly to discard.

·

Fluid should be able to wash out bits of metal

away from the cutting area.

·

The diverse metal cutting fluids require

distinctive application techniques; these incorporate brushing, flooding,

spraying, misting, and dripping. The most widely recognized and used technique

is a Jet method in which liquid is being sprayed to the cutting workpieces.

Non-Cutting Functions

· The selection of a fluid/coolant should also

consider its effect, not just on the part being ground or machined or however

upon the nearby condition of the operation. These contemplations would

incorporate the:

·

Addition of rust inhibitors to control

consumption

·

Stink (scent) protection from keeping the

development of poisonous vapor

·

Adhesive resistance to prevent waste formation

on the finishing product

·

Operator health and nature-friendly

·

Disposability which, contingent upon synthetic

substance, may go under certain ecological restrictions

Cutting Fluid

Maintenance

Cutting fluids lose its quality after some time because of

oil system contamination. Most common type of degradation in the form of tramp

oil, otherwise called sump oil, which is undesirable oil that has blended with

cutting fluid. It begins as grease oil that leaks out from the sideways and

washes into the coolant blend, as the protection film with which a steel

provider coats their items to avert rusting, or as pressure driven oil spills.

Skimmers are utilized to isolate the tramp oil from the

coolant. These are typically slowly rotating vertical disks that are partially

submerged beneath the coolant level in the primary supply. As the disk turns

the tramp oil sticks to each side of the plate to be scratched off by two

wipers previously the plate goes back through the coolant. The wipers are a

channel that at that point diverts the tramp oil to a holder where it is

gathered for waste disposal. Floating waste is additionally utilized as a part

of these situations where temperature or the amount of oil in the water becomes

too much.

Support and checking of the fluids are essential for helpful

fluid life. Some portion of this is in the care and tidiness of the machine

apparatuses themselves. Monitoring involves health and safety checks utilizing

the proper test, including:

·

Refractometers, which are utilized to decide the

aggregate sum of soluble in a solution.

·

Tests for PH levels and alkalinity (corrosive

parts) are additionally valuable.

·

Titration Kits, who are utilized to break down

fluid concentration in metal-cutting fluids sullied with tramp oils.