In

recent years, shops have experienced market changes that continue to impact how

parts are manufactured. Shorter lead times, reduced lot sizes and the drive to

eliminate inventory have conspired to change the manufacturing process.

In the

current manufacturing process adapted for the machining of metal parts needs a

milling machine to mill, a turning machine to turn, a drill press to make holes

and so on. Each operation was an incremental step in the manufacturing

process--ultimately resulting in a completely machined part. Shorter lead

times, reduced lot sizes and the drive to eliminate inventory have conspired to

change the manufacturing process.

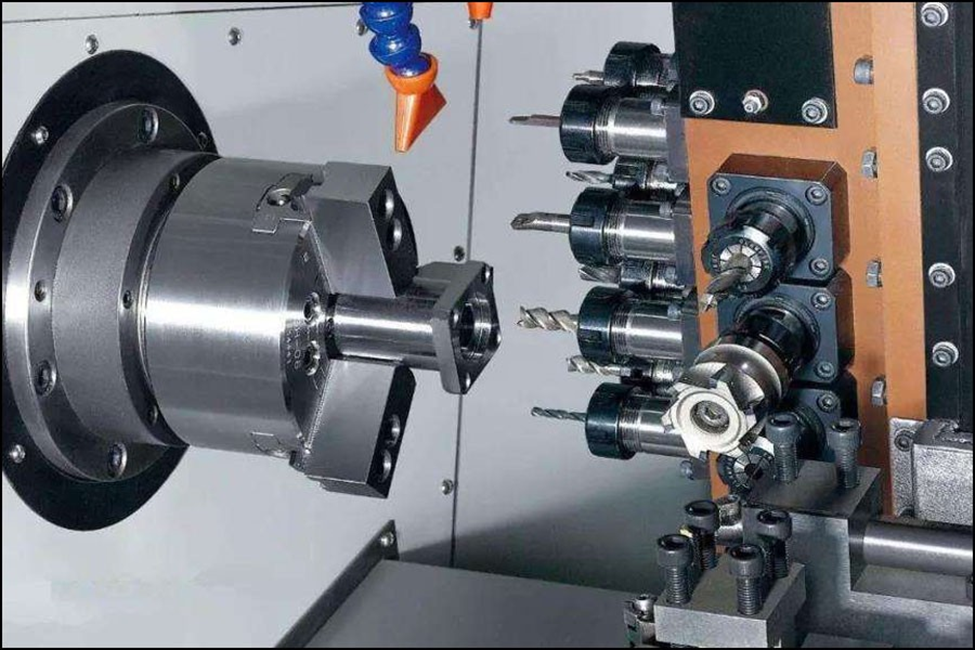

The Turn/Mill technology will enable to complete

most of the operations on a workpiece in a single setting. The turn-mill

machine brings advantages of access to part geometric features that previously

would require secondary operations. This reduction of clamping time avoids the

error accumulation caused by the conversion of positioning datum. Thus

improving the machining accuracy resulting in enhancement of throughput yield.

Additionally this technology provides the

ability to reduce production leadtime, improve machining accuracy, reduce floor

space, lower operating expenses, reduce operator requirements and improve the

work environment.